RFP Group is ready to commission the second wood processing plant in the PSEDA Komsomolsk

Construction of RFP Group enterprise in Amursk was completed as early as in December 2016; however, it was not commissioned officially, but it operates in a testing mode (2.1 thousand cubic meters were produced totally in the second quarter against the announced annual production volume of 230 thousand cubic meters). Equipment debugging, generation assembling and construction of drying chambers are continued at the plant. The line should be solemnly launched during the days of the Third Eastern Economic Forum.

Фото: Дмитрий Щербаков 12

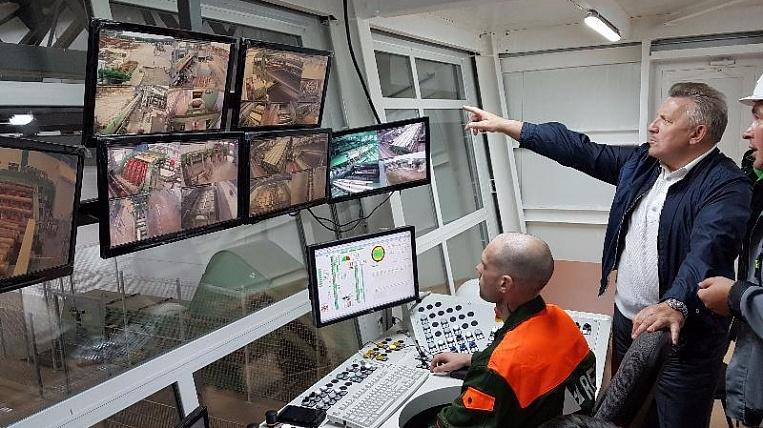

Фото: Дмитрий Щербаков 12 In 2012, RFP Group holding launched the rotary-cut veneer plant in Amursk; 152 thousand cubic meters of goods were produced in 2016, and 120 cubic meters within seven months of 2017. The enterprise reached 90% of the project capacity of 300 thousand cubic meters a year. In September, the second plant to produce timber materials is to launch complex testing involving 72-hour operation of all equipment under maximum load. "Official opening ceremony is planned to take place at the Eastern Economic Forum, it will be a remote ceremony. Here, at the site itself, the communications center shall be arranged, and the line shall be launched under a command," says Vasily Shikhalev, Executive Director of Amur Timber Company LLC.

The enterprise is to reach its design capacity in 2018; it will be, according to his estimations, over 20 thousand of timber materials a month. 102 million USD have been invested to the plant, according to the Executive Director: all outside financing "has been formalized in full amount, remaining works which are to be completed, have all the necessary funding." Equipment for the second enterprise was imported from Austria. "If two plants are launched at full design capacity, we will be able to process up to 900-1,000 million cubic meters of timber a year. The Group harvests around 2.4 million cubic meters of timber a year over Khabarovsky Krai only. So far we are testing the equipment, and sometimes we buy raw materials at the domestic market. All logistics for raw materials supply has been tried by the first plant already," tells Vasily Shikhalev.

Starting from 2013, 42% of RFP Group belong to the Russian-Chinese Investment Fund created by the Russian Fund of Direct Investments and China Investment Сorporation. The Company established the Far East Center for Deep Wood Processing in Amursk to increase business capitalization from 2008. The project estimated at 12 billion rubles, consists of three stages. The first two stages have been actually completed by the company; the third stage is construction of plant to produce 100 thousand fuelwood pellets from wood production wastes which are so far being disposed of by the enterprise's boiler plant. The wastes may be also used for production of MDF, chipboard, and cellulose. The company has already invested 10.4 billion rubles to the project, the principal creditor being Vnesheconombank.

While bringing the second stage of the project for deep wood processing to its completion, the holding is preparing to implement the third stage, which is construction of pellet producing plant. So far, the production wastes are partly sent to the energy producing enterprises of Amur District, and partly to the plant's own boiler, and some very small quantities are exported to PRC. "At the moment, selection of supplier of the principal technological equipment for the third stage of the project is under way. This year we are going to draw up a budget, at the same time we are working out our sources of financing. But all this is nearer to 2018-2019," says Vasily Shikhalev. According to him, the company is planning to complete project works during the winter, and to proceed with the major part of construction works in the next year. "This plant is not so big, as the first two plants," he clarifies. At the same time, according to Vasily Shikhalev's estimations, the Russian domestic market is not yet ready to consume pellets, because of low cost of alternative heating sources and absence of domestically produced boilers suitable for this technology.

Having become PSEDA resident, RFP Group enterprises haven't used the opportunity to get infrastructure support from the government. "In our operating activities, we felt the benefits of the resident's status, first of all, from the tax component. We haven't intentionally calculated the amount of savings, but the most noticeable thing is reduced payments to the social funds, since we have over 720 employees. As to the property tax and the profit tax, there used to be regional government support in regards to them. So far we are only approaching to the operational plus: the second plant has not been commissioned yet, but the expenses have been already incurred," says the top manager. Tax benefits, he admits, significantly reduce the project payback period. PSEDA benefits make even not the most economically profitable project effective. "It seems that, a trifle here, a trifle there, but when you distribute the cash flows by years, it turns out that the project can be implemented already," notes Vasily Shikhalev.

"For residents which are coming to PSEDA, the first indicator now is the population employment rate. But when all PSEDA residents start operating at full capacity and paying taxes in full amount, Khabarovsky Krai should become a self-sufficient region, fully covering its own needs. Our global maximum task is just that. So far our demands are covered by budget resources at 85%," says Vyacheslav Shport, Governor of Khabarovsky Krai. According to him, the Government should provide comfortable living conditions for the employees of the new enterprises: kindergartens, cultural and healthcare facilities, and housing. These are the tasks solved by such programs as the long-term plan for comprehensive development of Komsomolsk-na-Amure.

Dmitry Shcherbakov На БАМе в Забайкалье появилась новая грузовая площадка

На БАМе в Забайкалье появилась новая грузовая площадка

Меню с ягелем и локальными деликатесами разработали участники гастрофестиваля в Забайкалье

Меню с ягелем и локальными деликатесами разработали участники гастрофестиваля в Забайкалье

Цех для обработки металлоконструкций появится в Приморье

Цех для обработки металлоконструкций появится в Приморье

Мир возможностей Чукотки откроют гости на выставке «Улица Дальнего Востока»

Мир возможностей Чукотки откроют гости на выставке «Улица Дальнего Востока»

МЧС России: Семь человек спасены при пожаре в больнице Приморья

МЧС России: Семь человек спасены при пожаре в больнице Приморья

В зоне правительственного внимания

В зоне правительственного внимания

Киль подкачал

Киль подкачал

Заработал закон, обязывающий банки приостанавливать подозрительные переводы

Заработал закон, обязывающий банки приостанавливать подозрительные переводы

Пульс угля — 22 июля: угольная промышленность в моменте

Пульс угля — 22 июля: угольная промышленность в моменте

Бюллетень EastRussia: отраслевой обзор сельского хозяйства ДФО — лето 2024

Бюллетень EastRussia: отраслевой обзор сельского хозяйства ДФО — лето 2024

«На гребне!» гастрономических изысков

«На гребне!» гастрономических изысков